An active interior or exterior coating, a multilayer, breathable, heat reflective de-moisturising system.

Simple heat reflective coating for e.g. external roof surfaces has been around for a while and it is reasonably effective for reducing heat from direct sunlight, however it has significant limits.

The Double Hybrid Membrane Technology manages IR and UV radiation as well as moisture in the air. Moisture has a high specific heat capacity, hence reduction of moisture reduces heat transfer (loss or gain) dramatically. Just 4% of moisture will reduce the effectiveness of insulation by 50%.

Insulation systems are designed to absorb heat energy, i.e. only slowing down – not avoiding – the transfer rate of heat energy. Reflecting heat (radiation) and repelling heat energy contained in moisture avoids absorption and hence the transfer (conduct) of heat through walls and roofs.

- Up to 40% energy and CO2 savings

- Works on internal and external surfaces.

- Improved R-value from 0.74 to 2.65 W/m2K on a 24 cm brick wall with interior and exterior plaster

- Moisture is a key contributor to the “sick building” syndrome. Poor indoor air quality, cold walls, mould contribute to allergies and discomfort. DHMb technology keeps heat energy and moisture from buildings, whether interior or exterior walls.

- Also walls (specifically external walls) are more prone to deposits algae and mould. (note difference between units)

- Can be used in any building, Heritage, New construction, renovation, structural, removal of heat bridges

Contrary to static insulation, such as styro foam, mineral wool and glass fibre, the dynamic system of DHMb, minimises condensation as heat conduction, and as a result, temperature differences are minimised.

Reduction of condensation improves the heat conservation dramatically.

At the same time moisture will be removed from the base material. Walls will be dry and indoor air quality improved. Dry surfaces are resistant to mould and bacteria.

Also water vapour absorbs heat energy and removes the energy from a space, whereas static insulation is a resistance to heat transfer; any absorbed energy is trapped and then released with a time delay. The dynamic DHMb technology avoids this loss of energy, resulting in reduced cost and CO2 emissions.

The technology is proven in more than 10,000 buildings around the world, in various conditions.

Watch a short youtube video on the working principle: https://www.youtube.com/watch?v=GB6UPMtv2T8

Watch a 16 min video on information about the company, product and projects, please click here: https://www.youtube.com/watch?v=IdXMdMN1EPI

Download a brochure: click here

How does it work?

A coating, applied like paint, reflects ultraviolet and infrared radiation, it repels H2O molecules, a micro membrane pumps moisture from the base. Heated by IR and UV radiation, the H2O molecules, and with them the contained heat energy, are transported away. This has many very positive effects

- Less energy – Low energy bills

- Less moisture – Dry walls

- Less odour – clean air

- Less mould and dust – excellent Indoor Air Quality

- No germs adhere to surface – Hygienic climate

- Less fading – Bright colours and long lasting surfaces

It is a clever combination of heat reflection, moisture management and high breathability:

Click on picture to watch Youtube video

There are now more than 10,000 buildings coated with MIG-ESP coating

- new and historic buildings

- in hot climate (India, Cyprus, Israel, China)

- Humid climate (Thailand, China)

- and cold climate (Europe, Canada)

Case Studies:

- The 2 townhouses pictured above have been built at the same time (appox. 5 years old). The house on the left is painted with conventional paint and clearly shows a change of colour due to build-up of dirt and pollen. The one on the right is coated with MIG-ESP and looks like new. Any dirt and pollen is repelled along with water.

- A school canteen near the German city of Paderborn has been coated with MIG-ESP. When I visited shortly after the lunch break (kitchen still in operation) there was no obvious smell of any food.

- The laundry of a 7-apartment building where all tenants have their own washing machine and drier was very dry and did not have the typical soapy smell. Heating costs have been reduced by 70%.

This building demonstrated a return of investment after 2.7 years. If a building or a space is due for a renovation anyway, the additional cost for material is relatively small as the majority of the total cost is labour. - In the General Manager’s office the heating panels have been permanently removed, during winter it has been proven that they are no longer required (the rest of the building has heating)

- Applied in a bathroom, it shows significant less condensation hence reducing the risk of mould.

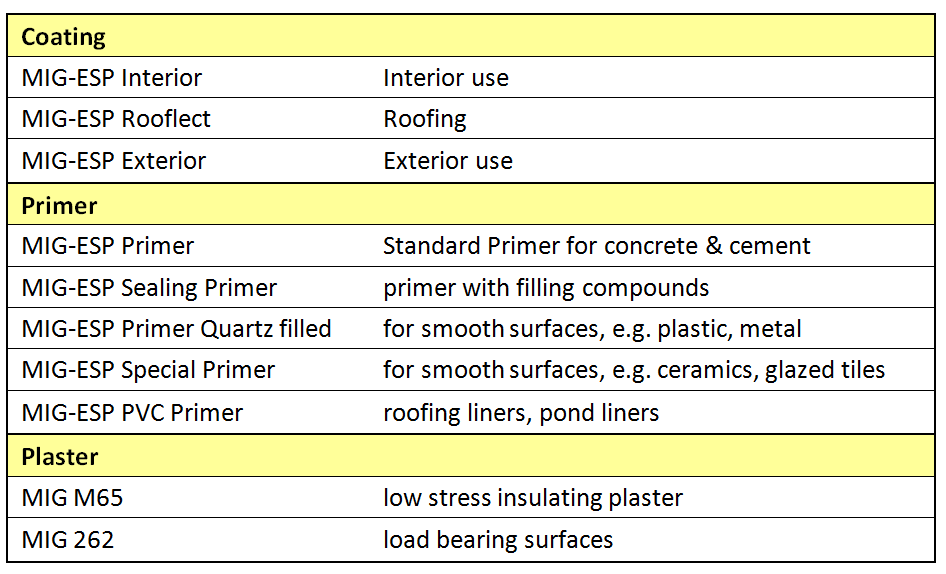

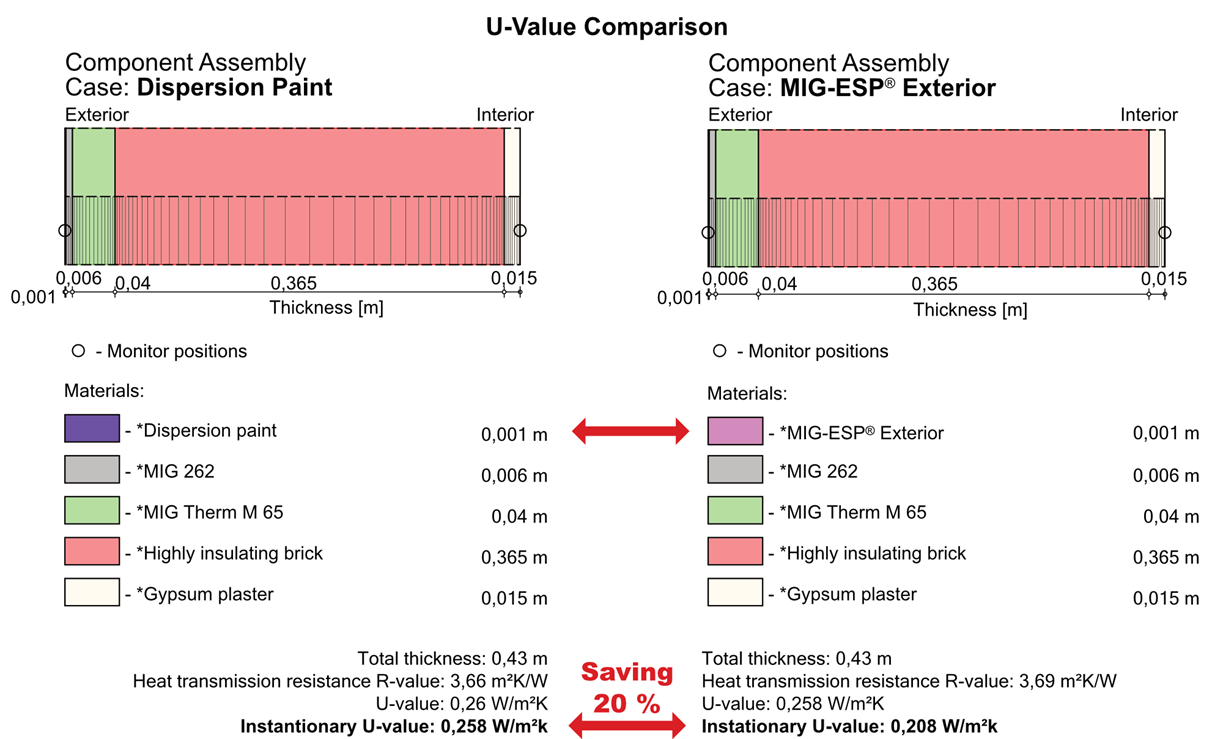

Product application: Just like paint. Depending on the subsurface various primers are provided. Also there are coatings for interior, exterior and roofs.

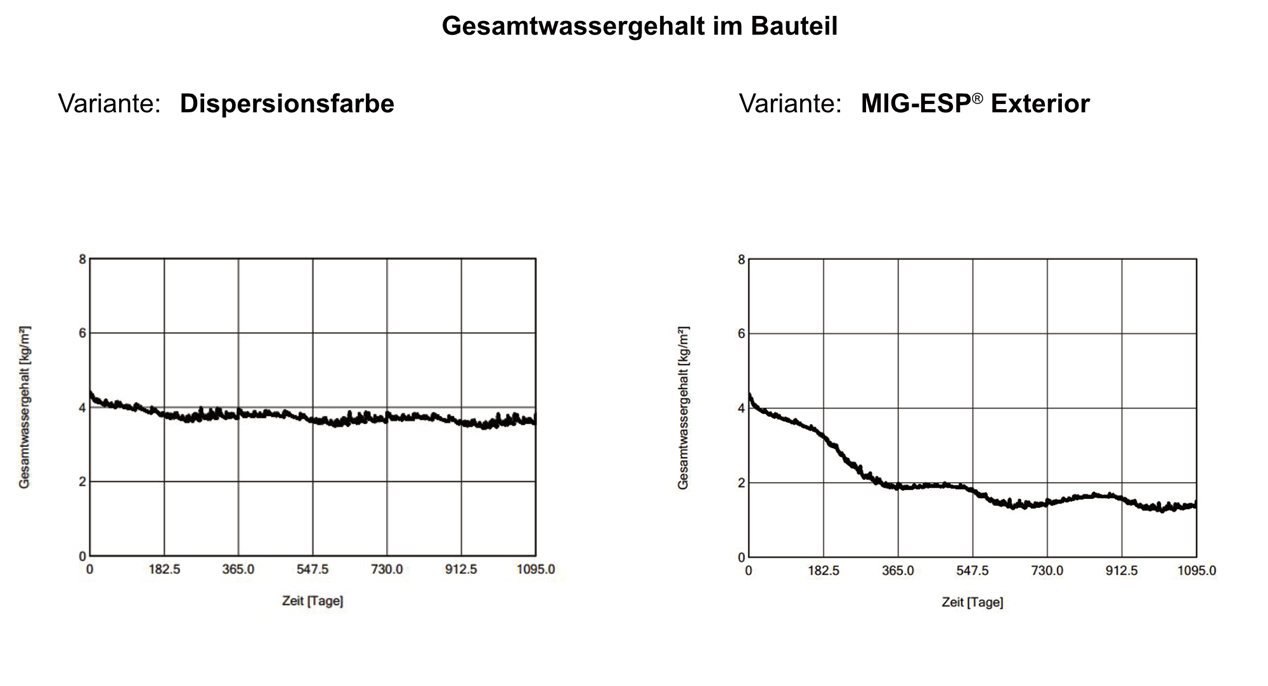

Moisture Management

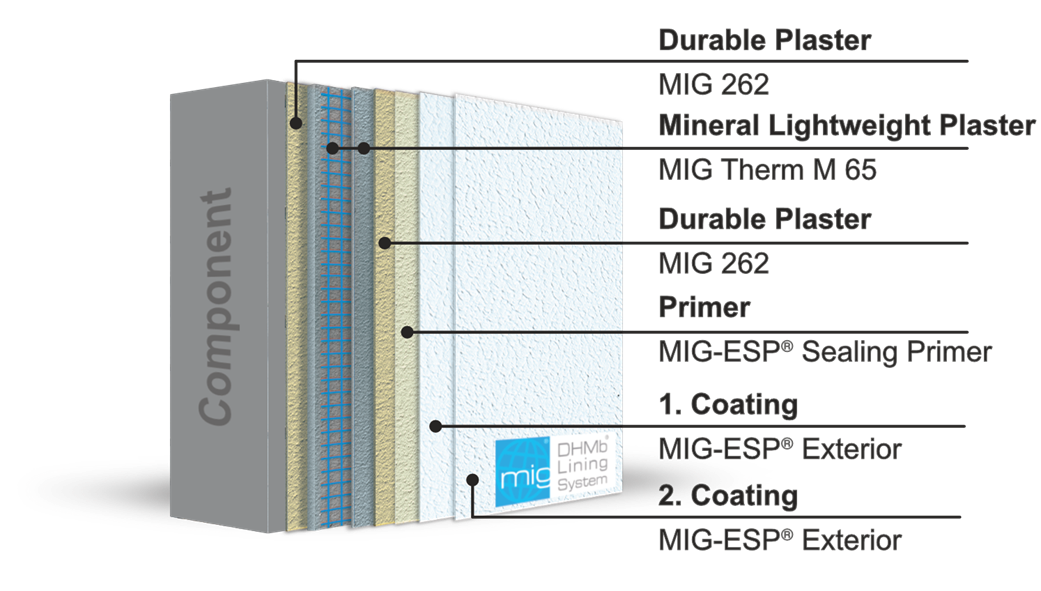

comparing standard exterior paint with MIG-ESP Exterior

MIG ESP System

Coating in combination with the appropriate primer can be used on most surfaces. MIG-ESP plaster is recommended but not a prerequisite.

MIG-ESP System Exterior

improving R-value (Transmission Resistance value) / reducing U-value

Please note that the single change is the exterior coating, does not take impact from MIG plaster products into account.

A 24 cm brick wall with interior and exterior plaster demonstrated an improved R-value from 0.74 to 2.65 W/m2K

Reference Sites

ToHA Building Tel Aviv, Israel

MIG-ESP® Exterior

chosen for

– bright colours, no discolouration

– Non-flammable

– replacing mineral wool, it saved 2.5 months in construction time, while achieving LEED platinum standard

60 residential units in Saragossa, Spain – 2015

Siemens building in Shanghai, China

– interior and exterior coating

– replacing mineral wool which was ineffective due to humidity

Slobodan Skerovic High School, Podgorica, Montenegro

Salinator Penning Haus anno 1563, Salzkotten, Germany

This building won a facade competition

– MIG products are approved by the States Monument Office in Münster, Germany

Drivers for choosing MIG products:

– Non-flammable,

– Solvent-free

– Thin-layer insulation to keep the historical facade while improving energy efficiency

Restaurant and Fitness Club

Mensa – Paderborn, Germany

– Canteen for 400 students

– reduced odor

– reduced dust

– improved climate

Müller Elektronik GmbH, Salzkotten, Germany

– 3,000m2 exterior

– 9,000m2 interior

– bright colours and no fading

Guanyin Temple in Dongguan, China

Ceiling of an industrial bakery chain

– ceiling had to be repainted several times per year due to mould, with MIG-ESP mould did not return